This is a hot rod. If you are looking for a pristine MGB you must look elsewhere.

| Good tires, reasonable paint, plain wheels, new top |  |

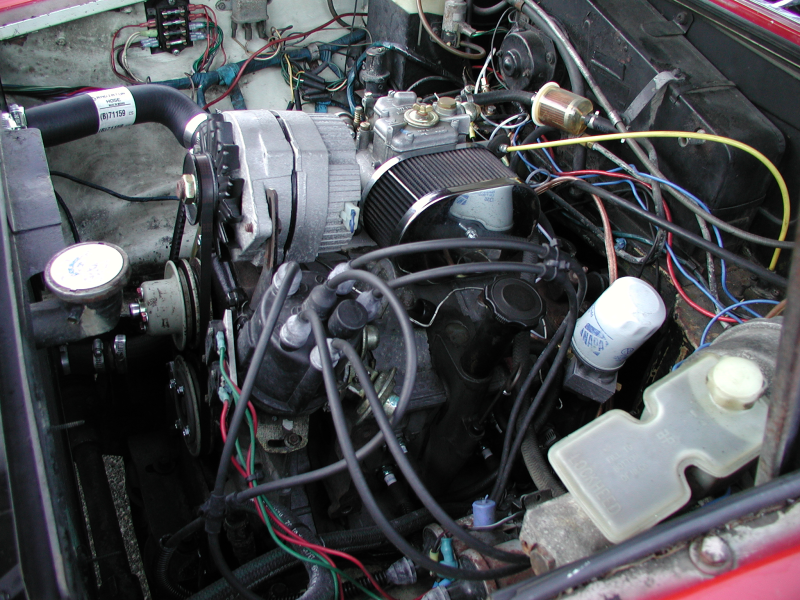

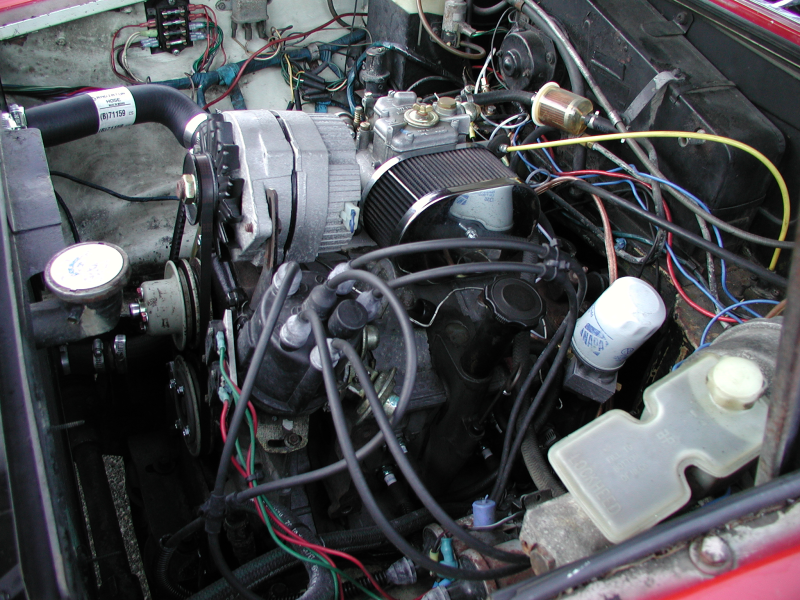

| Power brake booster, one-wire alternator, the Weber |  |

| Uses an electric radiator fan; electronic ignition; oil pressure gauge fed through aluminum block beneath oil filter |  |

| Recored MG radiator. Note heat shield above header on passenger side. Good view of the general layout. |  |

| That white scrape on the door shows the original paint color. |  |

| Roll bar and new top visible. |  |

| Tattered interior visible. It does NOT get better closer up. |  |

OTHER NOTES ON THE SWAP We had a drive line built from Mazda / MG parts. Keeping the manual transmission is easy, because of the hydraulic linkage. The torque reaction of the engine, a result of the not quite solid enough front motor mount, kept us from frying the tires off too much. If we did it again, we'd get a newer engine (12A) and its 5-Speed. The 13B was out of a Mazda Pickup. We used the pickup transmission. Our front engine mount was a length of large (3") steel angle iron, approx. 14" long, bolted to the factory mount location on the "timing cover" of the engine. The angle iron's lower leg ran forward of the upper leg. The lower leg of the angle iron rested on two engine mounts (with rubber isolators) from the pickup. The engine mounts have a stud on top and bottom - the lower studs were inserted in two holes we drilled in the MGB's front crossmember. If we were to do the swap again, those bottom mounting locations would be spread as wide as possible to better resist engine rotation due to torque. You can see the leading edge of this mount in this photo http:// www.plesba.com/images/mg/engine2.png -- the holes for the engine mounts are slotted. The rear crossmember was the MGB unit with a small, simple "L" bracket welded on its front face to mate with the Mazda's transmission mount. Also from angle iron I believe, probably 1.25" size. Engine positioning was a little tricky, since the Mazda's oil pan wants to occupy the same space as the MGB's front crossmember. We chose to position the engine/trans as far back and as far down as was practical. Our final location had the lowest part of the Mazda's oil pan behind the MGB front crossmember, and perhaps 1.25" between the front crossmember and the higher part of the oil pan. This made the transmission mount easy, as described above. Our engine location required two body modifcations for clearance: the firewall behind the engine, specifically behind the clutch slave cylinder (mounted at the eleven o'clock position looking forward) was relieved perhaps an inch. Were we to do the swap again, we'd have fabricated a "negative dome" from sheetmetal and cut-and-welded that into the firewall at the interference location. The shifter for the manual transmission required cutting (minor) of the hole in the transmission tunnel. The Mazda's exhaust ports were very close to the right side frame rail. We had a header flange for the motor, and fabricated head pipes from some mild steel close-radius ell weld pipe fittings, 1.5" or 2" (can't recall) size. With the fittings in place, twin pipes went back and then Y'd into a single exhaust system. The Mazda backfired a bit when first installed, and we lost a couple mufflers. :) The radiator is an MGB unit, with the coolant inlet & outlet moved to the other side of the upper and lower radiator tanks to match up with the Mazda's hose locations.